Annealing is a crucial process in the world of blacksmithing. It involves heating a metal to a specific temperature, holding it there for a period of time, and then allowing it to cool slowly. This process changes the structure of the metal, making it softer and more malleable.

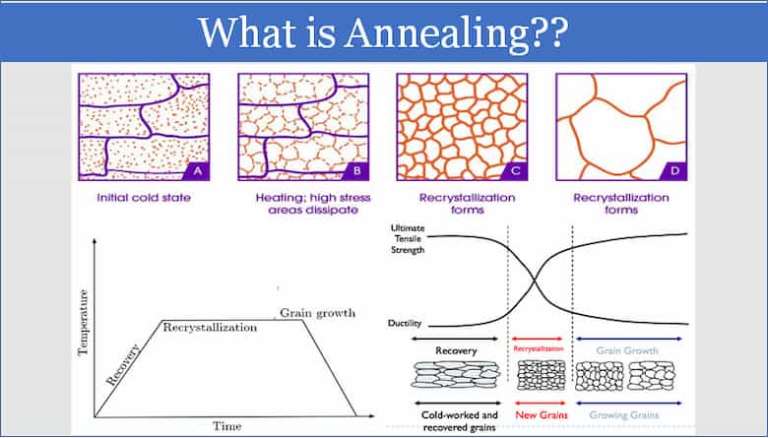

The main purpose of annealing is to relieve stress and improve workability. When metals are worked by hammering or bending, they can become brittle and develop internal stresses that weaken their structure. Annealing helps to remove these stresses by causing the metal’s crystals to recrystallize into a more relaxed state.

The annealing process typically involves three stages: heating, soaking, and cooling. The first stage involves heating the metal slowly until it reaches its critical temperature – the point at which its crystal structure begins to change. The second stage involves holding the metal at this temperature for a period of time – usually several hours – so that its entire mass can reach an even heat throughout. Finally, the third stage is cooling down slowly with controlled rate until room temperature is reached.

Different metals require different temperatures for annealing; copper should be heated around 600-700 degrees Celsius while steel requires higher temperatures between 750-800 degrees Celsius or beyond depending on carbon content. Some metals may also require specialized atmospheres during annealing such as nitrogen or hydrogen gas depending on their reactivity levels.

In conclusion, annealing plays an important role in modern blacksmithing as it allows smiths to work with various types of metals easily and safely without damaging them irreparably through cracking or fracturing when forging complex shapes or intricate designs out from raw materials like ingots or castings yielding high quality final products with superior mechanical properties for intended applications ranging from decorative objects to industrial machinery parts among others where strength, durability or flexibility are paramount factors affecting performance over time under varying conditions encountered in use thereby aiding blacksmiths achieve desired results consistently.