Kiln Construction Using Fire Bricks: A Guide for Modern Blacksmiths

Introduction:

For blacksmiths, kilns are essential tools that enable them to heat-treat metals, anneal, and temper their creations. Kilns constructed using fire bricks provide excellent insulation and durability needed for high-temperature applications. In this guide, we will explore the process of kiln construction using fire bricks in detail.

Choosing the Right Fire Bricks:

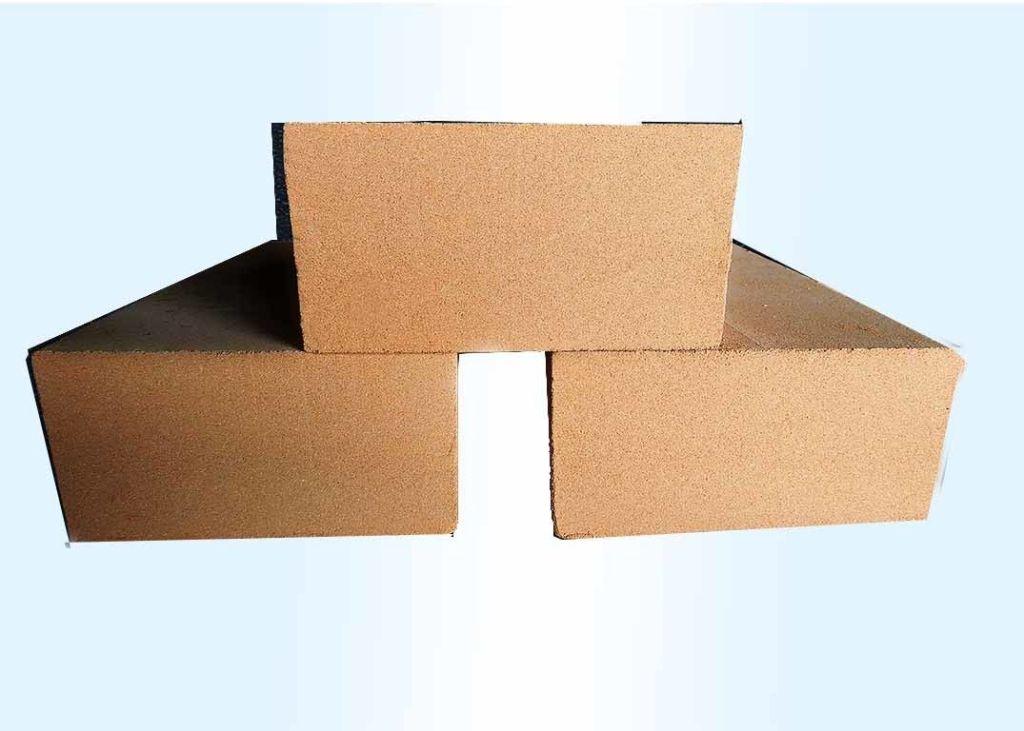

The first step in building a kiln is selecting the right type of fire bricks. There are several varieties available on the market, each with its own unique properties. Here are some commonly used fire brick types:

1. Dense Fire Bricks: These bricks have a higher density and lower porosity than other types. They offer excellent thermal conductivity and mechanical strength but tend to be more expensive.

2. Insulating Fire Bricks (IFBs): IFBs have low thermal conductivity due to their porous structure. They are lightweight and ideal for insulating purposes but may not withstand heavy loads or extreme temperatures as well as dense fire bricks.

3. Super Duty Fire Bricks: These bricks can handle extremely high temperatures (up to 3200°F/1760°C) and are often used in industrial applications where durability is crucial.

Designing Your Kiln:

Before construction begins, it’s important to design your kiln based on your specific needs and available resources. Consider factors such as size requirements, fuel source availability, temperature range required, and ventilation options.

Building Process:

1. Foundation: Start by constructing a solid foundation for your kiln using concrete or refractory materials capable of supporting the weight of the entire structure.

2. Base Layer: Lay down a layer of fire-resistant mortar on top of the foundation, ensuring an even thickness throughout.

3. First Course: Begin laying the first course of fire bricks around the perimeter of your base layer with mortar joints between them. Use a trowel to ensure the bricks are level and aligned.

4. Subsequent Courses: Continue adding more courses of fire bricks, staggering each row to create a stable structure. Apply mortar between each brick and use a spirit level to maintain evenness.

5. Arch Construction: If your kiln design includes an arched roof, construct temporary wooden or metal supports to shape the arch as you lay the bricks. Once the bricks are in place, remove the supports and fill any gaps with mortar.

6. Insulation Layer: For improved energy efficiency, consider adding an insulation layer using ceramic fiber blankets or insulating fire bricks around the walls of your kiln.

7. Ventilation and Flue System: Install appropriate ventilation openings or flues in your kiln design to allow for proper airflow and smoke management during operation.

8. Doorway: Leave space for a door that fits securely into your kiln design, allowing easy access for loading and unloading materials.

Safety Considerations:

When constructing a kiln using fire bricks, safety should always be prioritized:

1. Protective Gear: Wear appropriate protective gear such as gloves, goggles, and heat-resistant clothing when working with hot materials.

2. Adequate Ventilation: Ensure proper ventilation in your workspace to prevent the buildup of harmful gases emitted during firing processes.

3. Fire Safety Measures: Have fire extinguishers nearby and follow all necessary precautions to minimize the risk of accidental fires or overheating.

Conclusion:

Constructing a kiln using fire bricks is an essential skill for modern blacksmiths looking to expand their capabilities in metalworking processes such as heat treatment and annealing. By choosing suitable fire brick types, designing carefully, following proper construction techniques, and considering safety measures throughout the process, you can build a reliable kiln that will serve you well in enhancing your blacksmithing craft.