Bloomery Troubleshooting Tips for Modern Blacksmiths

As a blacksmith, you know how important it is to have a functioning bloomery. It’s the heart of your operation and without it, you can’t make iron or steel. However, like any piece of machinery, problems can arise with your bloomery that need to be addressed quickly in order to avoid setbacks in production. In this article, we’ll discuss some common bloomery troubleshooting tips that will help modern blacksmiths keep their operations running smoothly.

1. Inspect Your Bloomery Regularly

The key to preventing major issues with your bloomery is regular inspection and maintenance. Take the time to inspect your bloomery at least once a week (or more often if it’s heavily used) for signs of wear or damage. Look for cracks in the brickwork, loose mortar or bricks, and any signs of corrosion around the furnace doors.

2. Check Your Airflow

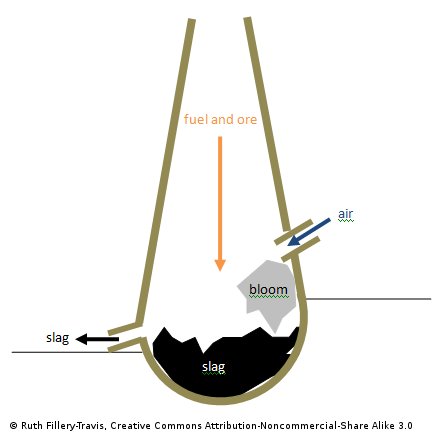

One of the most common issues found in malfunctioning bloomeries is poor airflow. This can lead to incomplete combustion and lower temperatures inside the furnace which can cause problems when trying to smelt iron or steel. Make sure your bellows are working properly and that there are no obstructions blocking air from entering the furnace.

3. Monitor Fuel Consumption

Another issue that can crop up with a poorly functioning bloomery is inefficient fuel consumption which leads to a higher cost per unit produced as well as environmental concerns due to excess emissions being released into the air during smelting processes.

To prevent this problem from occurring regularly monitor fuel consumption rates by measuring wood chips fed into burners over an hour-long period; compare results against expected values based on data sheets provided by manufacturers’ instructions manual available online or through customer service hotlines.

4. Keep Your Flux Levels Consistent

Flux plays an important role in reducing impurities during smelting processes but too much flux added may cause over-reduction which leads to low-quality product yield. Be sure to maintain a consistent level of flux throughout the smelting process and avoid adding too much at once.

5. Maintain a Consistent Temperature

Maintaining a consistent temperature in your bloomery is essential for successful iron or steel production. Ensure that there are no cold spots inside the furnace by regularly checking temperatures with a thermometer.

6. Address Corrosion Issues

Corrosion can occur on both the interior and exterior surfaces of your bloomery and can lead to structural damage if not addressed promptly. Regularly inspecting your bloomery for signs of corrosion (such as rust) and taking immediate action will extend its lifespan while preventing further damage.

7. Use High-Quality Fuel Sources

The quality of fuel you use can have a significant impact on the performance of your bloomery, so it’s important to invest in high-quality sources whenever possible.

Using well-seasoned hardwoods such as oak or hickory will produce cleaner burning wood chips compared to softwoods like pine which tend towards higher levels of creosote buildup leading to more frequent maintenance requirements down the line.

8. Know When To Seek Professional Help

If you’ve exhausted all troubleshooting tips but still experience issues with your bloomery, it may be time to seek professional help from experienced blacksmiths who specialize in these types of repairs.

Don’t hesitate – getting expert advice early on will save you both time, money, and potential long-term damages caused by neglect or improper handling practices that could compromise structural integrity rendering equipment unusable until costly repairs are made.

In conclusion, keeping up with regular inspection and maintenance, monitoring airflow rates/fuel consumption/temperature levels consistently along with using high-quality fuel sources are key steps modern blacksmiths should take when operating their own Bloomeries successfully without disruptions or unnecessary delays due malfunctioning equipment.

Remember: When all else fails don’t hesitate; seek professional help from experienced blacksmiths who specialize in these types of repairs; it’s worth the investment!